Slashing Prototype Lead Times, One Print at a Time

Ever wondered how you could slash production time from weeks to days, or eliminate the need to assemble a dozen parts, instead crafting a single, lightweight piece? Sounds like the future, right? But guess what—it’s happening today, thanks to large-format 3D printing. Forget what you know about slow, expensive traditional tooling. This changes the game. If you’re in aerospace, automotive, or any industry where design agility matters, this isn’t just an option anymore. It’s fast becoming a necessity to keep up.

How It Actually Works – A Reality Check

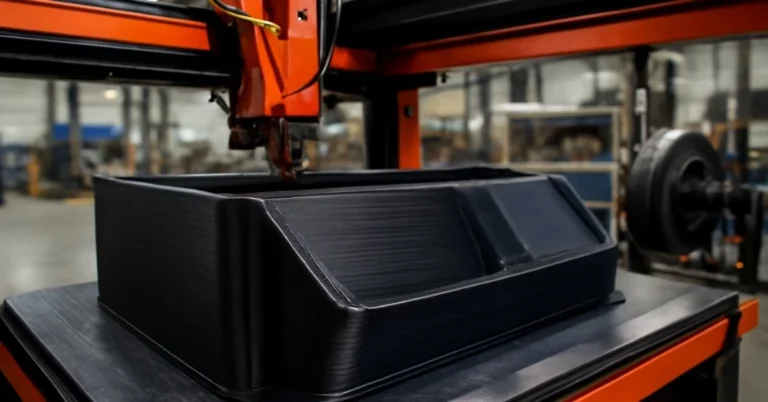

Okay, everyone talks about “layer-by-layer” printing. But let’s get specific about what that means when the parts are bigger than your desk. The real workhorse for large-format 3D printing is FDM (Fused Deposition Modeling). Think of a super-precise, robotic hot-glue gun laying down strands of tough plastic like ABS or Nylon. It’s not always pretty straight off the build plate, but it’s incredibly strong and practical.

Now, for parts that need more fine detail and less post-processing, SLS (Selective Laser Sintering) is the magic trick—a laser fusing powder into solid nylon, with no support structures to painfully remove. This technology is great for printing geometries that would otherwise be impossible or too costly to produce using traditional methods.

And here’s the kicker: this isn’t hobbyist printing scaled up. This is industrial-grade manufacturing. The tech may sound simple, but the possibilities are endless, allowing businesses to produce components that were once too expensive or just plain impossible to create any other way.

The Real Business Case: Advantages Beyond Size

Let’s be honest, “affordable” is relative. A large-format industrial printer isn’t cheap— we’re talking over $100,000 for some models. But the real savings? They’re in the details—or rather, in the lack of them. No expensive molds. No specialized tooling. That’s upfront cash that stays in your pocket.

Take Volkswagen’s Autoeuropa plant in Portugal. They didn’t just save a little; they saved over €325,000 in a single year by printing custom tooling in-house instead of outsourcing the work. That’s not just cost-effective; it’s a no-brainer for any operation tired of outsourcing delays and markups.

So, when it comes to printing custom tooling, prototypes, or even small production runs, the savings add up. Big-time.

From Aerospace to Hollywood: Where Large-Format Printing is Making Waves

Large-format 3D printing isn’t just a factory tool—it’s a true disruptor in industries ranging from aerospace to Hollywood. Here’s how:

Aerospace

Let’s talk about GE Aviation for a moment. They’ve taken 3D-printed fuel nozzles for their LEAP engine—and guess what? That one nozzle used to be 20 separate parts. Now, it’s a single component that weighs 25% less, improving fuel efficiency in a major way. This isn’t just about reducing part count—though that’s a huge win—it’s fundamentally about boosting performance and cutting costs in a way that traditional machining simply can’t match.

Automotive

In automotive manufacturing, parts like brackets or lightweight panels that are difficult to fabricate using traditional methods are now being printed in large formats. Volkswagen’s Autoeuropa plant has saved money by printing tooling and fixtures for their production line in-house, instead of outsourcing. And Ferrari has used 3D printing to create custom, lightweight interior parts, resulting in more efficient production times and a noticeable boost in product quality.

Construction

Here’s the thing—when it comes to construction, large-format 3D printing is downright game-changing. ICON, for example, has developed a Vulcan printer capable of building homes in just 24 hours, using less than $10,000 in materials. That’s not just revolutionary; it’s a viable path to affordable, sustainable housing. They’ve already printed homes in places like Austin, Texas, and with more projects in the works, this could very well be the future of how we build.

Entertainment & Prototyping

But wait—3D printing isn’t just for manufacturing parts. It’s making waves in Hollywood, too. On sets like The Mandalorian, they used large-format 3D printing to create full-scale props and detailed cockpit consoles. This allowed them to iterate rapidly on design ideas—making sure each piece was both functional and visually realistic. Honestly, the flexibility to produce fast, full-scale prototypes has made it a favorite tool for movie sets.

The Hurdles: A Candid Look at Limitations and Costs

The elephant in the room? Cost. Yes, it’s true—the initial investment for industrial-grade 3D printers can be a hefty one. But that cost is quickly offset by time savings and cost reductions in production. But it’s not just about the printer. Material costs can get steep, especially when you’re printing parts in high-performance polymers or metal alloys. These materials are more expensive than standard filaments.

Let’s be real—post-processing is another big one. A part that takes 24 hours to print might need another 8-10 hours of sanding, priming, and painting. The surface finish can be rough, and the layer lines are visible. That’s why we’ve invested in automated sanding systems to handle the bottleneck. It hurt our budget at first, but it cut our post-processing time by 70%. The moral of the story? Don’t underestimate the time and money required for finishing touches.

The Future of Large-Format 3D Printing: Bioprinting, Sustainability, and On-Demand Factories

Looking ahead, the future of 3D printing is looking sustainable and innovative. With more manufacturers adopting eco-friendly materials and methods, sustainability is at the forefront. Bioprinting—printing human tissues and organs—is on the rise, especially for medical applications. Imagine being able to print custom prosthetics or even skin grafts in the future. It’s no longer science fiction.

Moreover, AI-powered optimization will continue to improve the efficiency of 3D printing. AI-powered build simulations could even predict warping or material defects before the print even starts. The automation of the entire process will make large-format printing even faster and more reliable.

How to Choose a Partner: A 5-Point Checklist for Your Project

Alright, you’ve decided that large-format 3D printing is the way to go. Now, how do you choose a partner? Here’s a no-nonsense checklist:

1. Nail Down Your “Why.” Seriously. Are you making a one-off prototype for a trade show, or a functional part that needs to withstand real-world stress? This decision dictates everything that follows—the material, the technology, and the partner you choose.

2. Evaluate Their Materials Portfolio. Ask: Do they offer the certified materials you need, like aerospace-grade metals or flame-retardant plastics? Don’t settle for generic materials when you need specific performance features.

3. Ask About Tolerances and Post-Processing. Get specific: What’s the tolerance on a 1-meter part? Can they show you examples with the surface finish you require? This is non-negotiable when you’re aiming for high-performance parts.

4. Don’t Overlook Design Expertise. Seriously, do they offer DfAM (Design for Additive Manufacturing) services to optimize your part for 3D printing? This can save weight, reduce costs, and avoid printing issues.

5. Get a Detailed Quote. Don’t just ask for the base price. Get a breakdown of costs for printing, post-processing, and shipping, and ask for a timeline—because delays are costly.

Conclusion: Embrace the Future with Large-Format 3D Printing

Large-format 3D printing isn’t just the future—it’s here now, and it’s transforming industries across the globe. Whether it’s aerospace, automotive, or construction, this technology is enabling businesses to innovate, reduce costs, and speed up production like never before.

If you want to stay competitive, adopting this game-changing tech isn’t just optional—it’s a strategic move. So, what are you waiting for? Start exploring the potential of large-format 3D printing today, and give your projects a serious advantage.

Frequently Asked Questions (FAQs)

What are the most common materials used in large-format 3D printing?

You’ll typically see plastics like ABS and Nylon, metals like titanium and stainless steel, and composite materials like carbon fiber-reinforced filaments, depending on what the part needs to do.

How long does it take to print large parts?

It really depends on the size and complexity, but large parts can take anywhere from a few hours to several days.

Is large-format 3D printing eco-friendly?

It can be, especially when using recycled materials or biodegradable filaments, and by reducing material waste compared to traditional methods.

What industries benefit most from large-format 3D printing?

Industries such as aerospace, automotive, construction, and healthcare are all seeing significant benefits from large-format printing.

Can large-format 3D printing replace traditional manufacturing?

While it’s perfect for prototyping and low-volume production, traditional methods are still more cost-effective for high-volume manufacturing. That said, large-format 3D printing is increasingly bridging that gap.